GamePro – Gaming Cabinet for Reflex Gaming

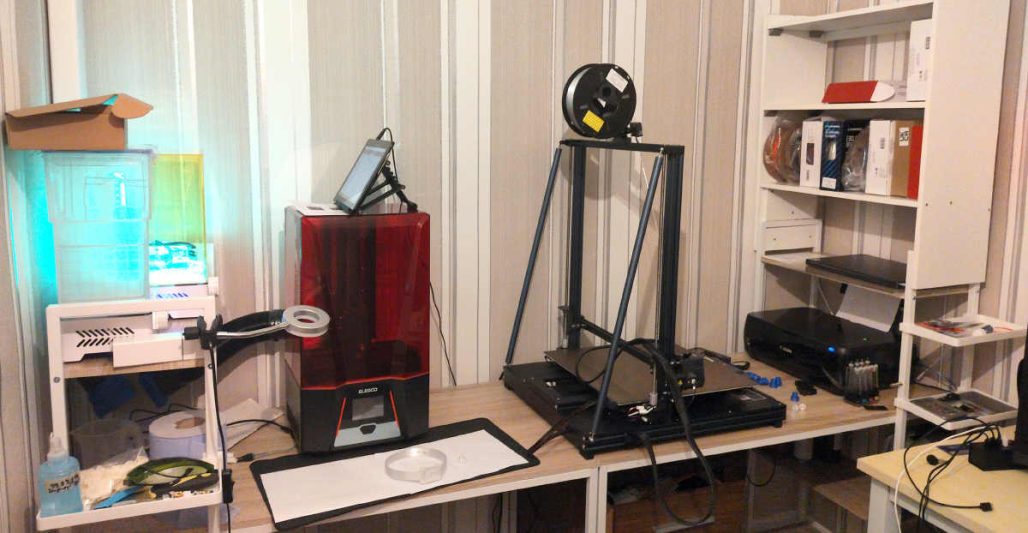

As I joined Reflex Gaming in 2016, I was given a task to develop / design a new cabinet for the digital market. Most of the company products were on a market for more than a decade and lost significant interest during that time. The company required this new cabinet to keep with demand of the digital gaming industry.

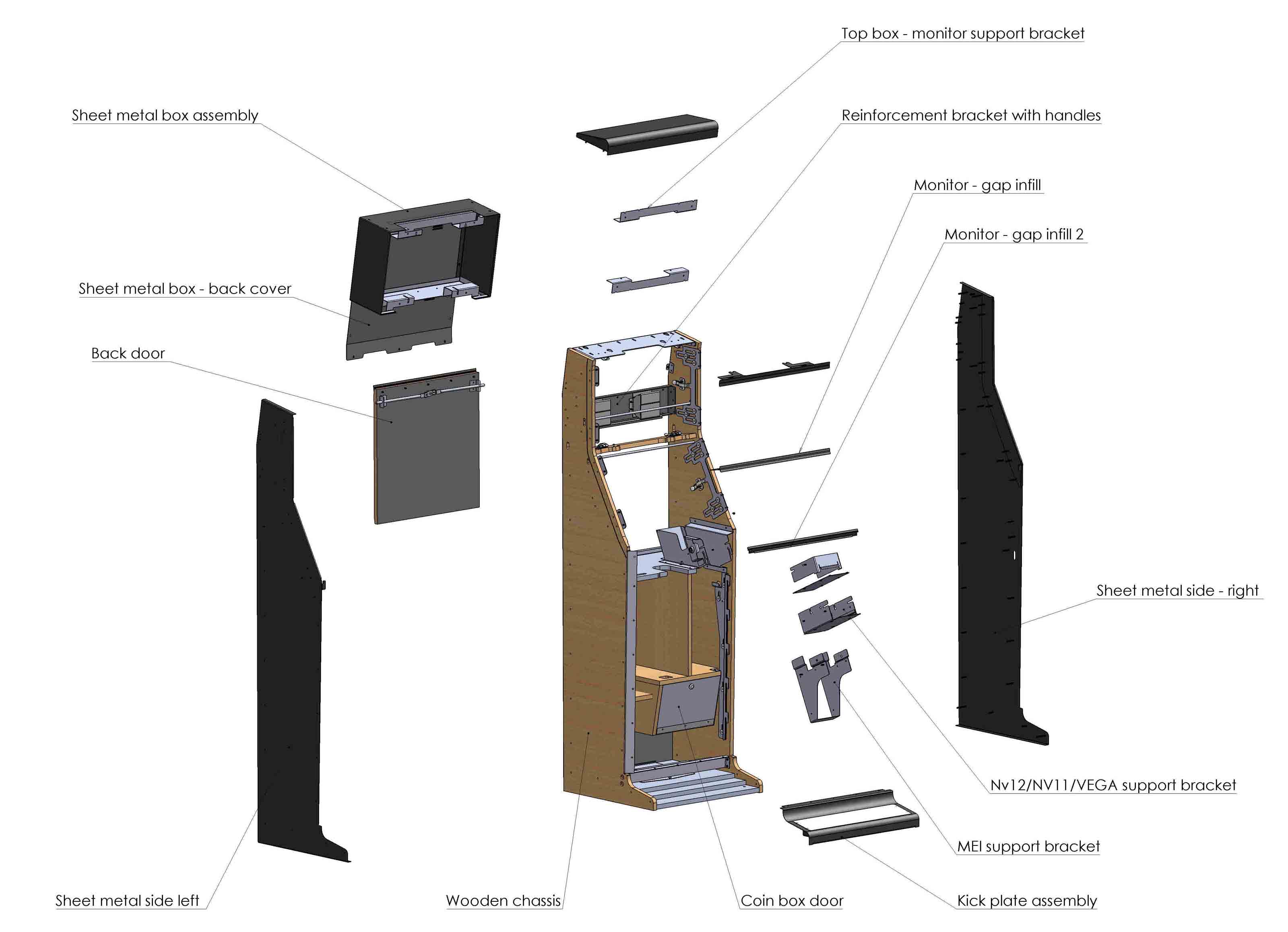

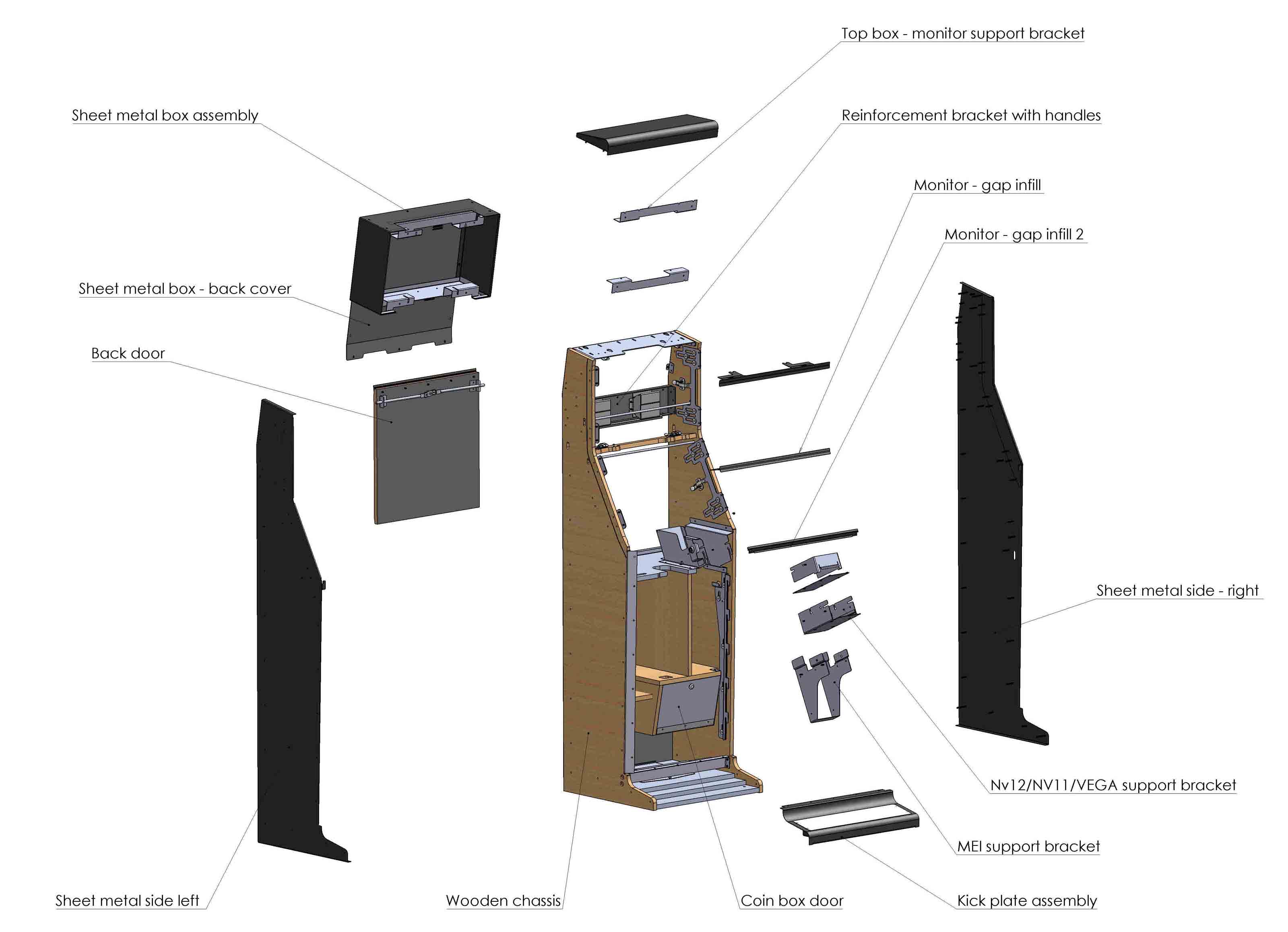

The initial concept of the new cabinet was based on a wooden chassis with metal covers attached on each side. This idea was supposed to give the cabinet “metal” look and provide extra security. It was also the cheapest way of fabricating the chassis comparing to completely metal design.

Picture.1 – Initial concept idea

It took around 6 month to bring the initial idea of this concept to life. During that time I was actively reviewing my work with the company management and making updates to the overall design.

One of the challenges for me was the design of the front plastic door. The cabinet required big door in order to allow easy access to internal technology and service maintenance. As the result, the overall height of the plastic door composed 1100mm with the overall width of 579mm. The tooling size was twice the size of the door and took around 3 days of machining time by subcontractor.

Picture.2 – Front plastic door design

It was very exiting for me to work with the design of the door as it was the biggest plastic moulded part in my career at that time. I spent around 2 weeks finalizing the design and during that time I made a number of changes to achieve the best draft angles, rigidity of the final part and molding performance. I was happy with the final result.

>Another plastic molded part of the cabinet was the coin tray. Comparing to the front door it was relatively simple part (pic. below).

Picture.3 – plastic coin tray design

When I was close to the finish line, the whole concept suddenly took an unexpected turn as the company management discovered a new metalwork supplier with attractive fabrication prices. The decision was made to convert the whole cabinet into the sheet metal design.

The conversion process took around 6 weeks and the cabinet was designed in 2 versions – “Triple” and “Twin” screen. Each version could be converted one into another with minimum modifications.

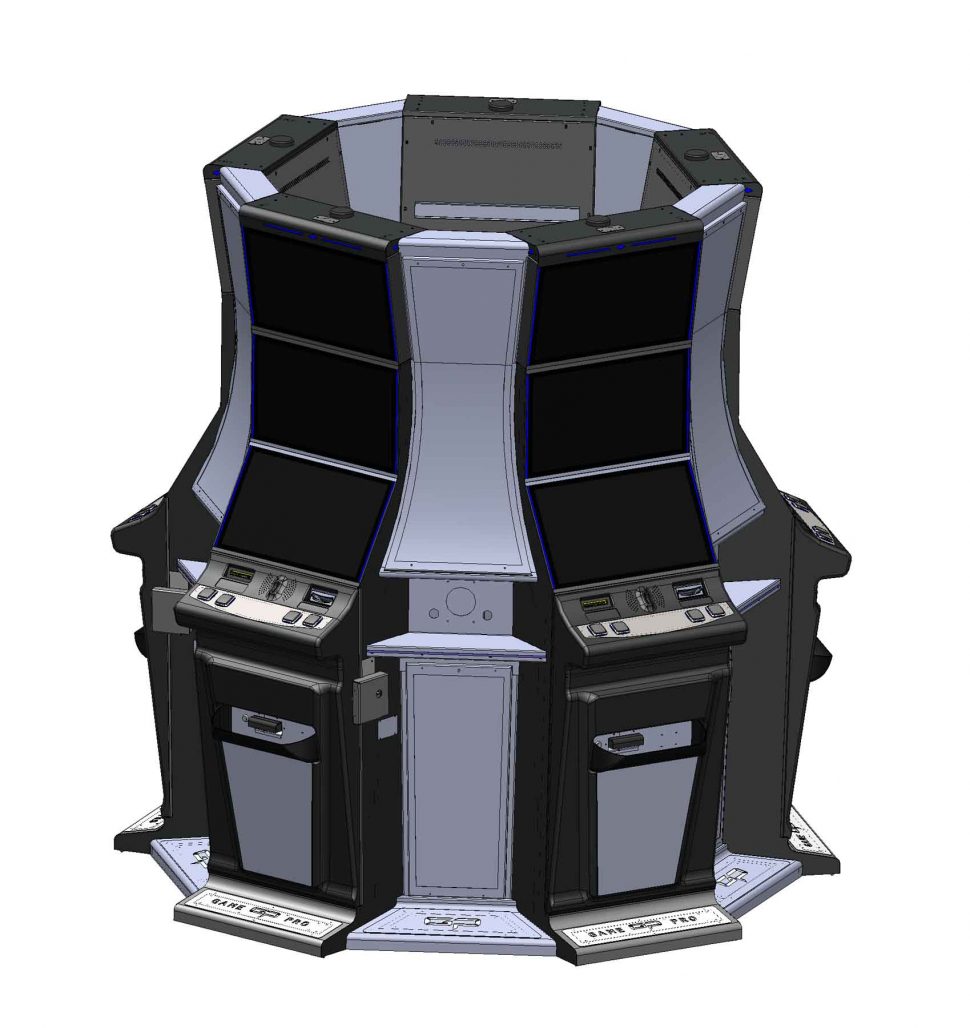

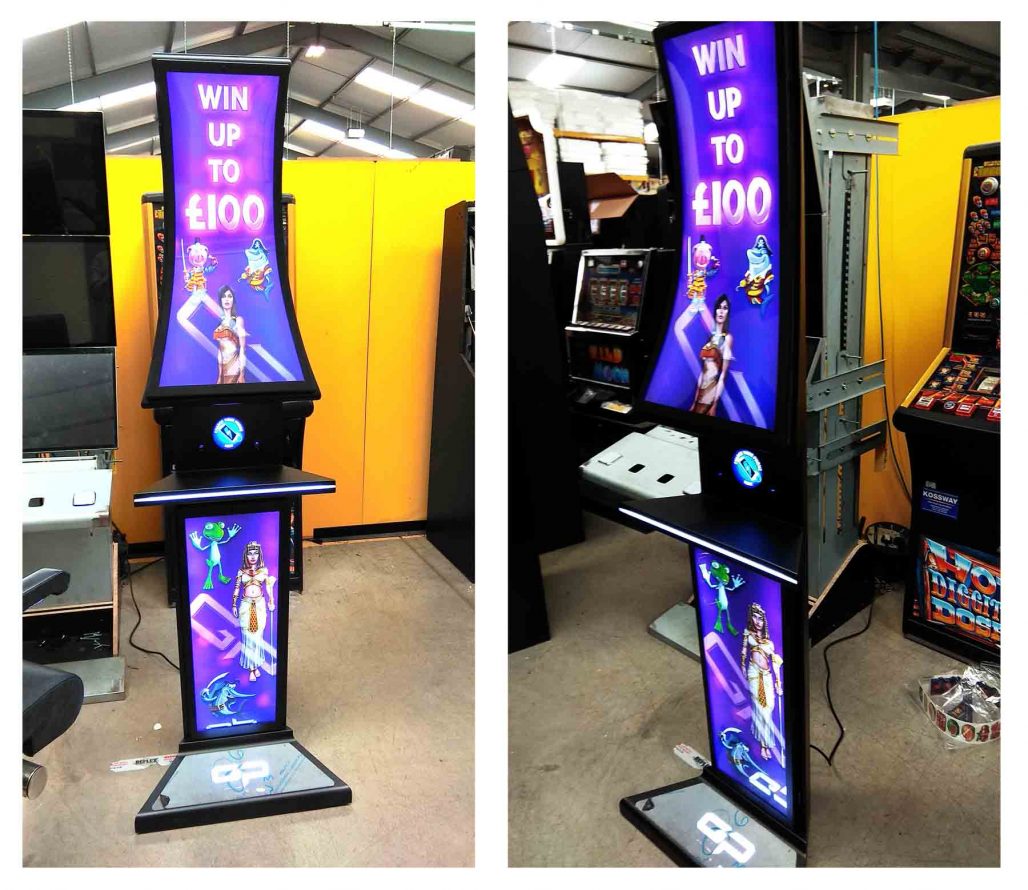

Picture.4 – GamePro cabinet – final result (Twin screen version on the left and Triple version on the right)

The cabinet received a lot of attention on the market and as a result became the company top selling product. I was happy to see the final result of my work and success of the product.